In the ever-expanding world of technology, the production of smart cards has become a cornerstone for many industries, including banking, telecommunications, healthcare, and security. These cards, which contain microchips embedded with critical data, serve as tools for secure identification, transactions, and access control. As demand for these cards continues to rise, manufacturers are constantly looking for ways to optimize production processes, ensuring high efficiency, reliability, and quality. One of the key components in enhancing the overall production process is the card packaging machine, which is responsible for the final stages of smart card production. These machines are crucial for sorting, counting, packaging, labeling, and ensuring the overall quality of the cards before they are shipped to customers.

This paper explores the significant benefits of incorporating card packaging machines in the smart card production line, focusing on efficiency improvements, cost reduction, product protection, and the overall impact on the manufacturing process.

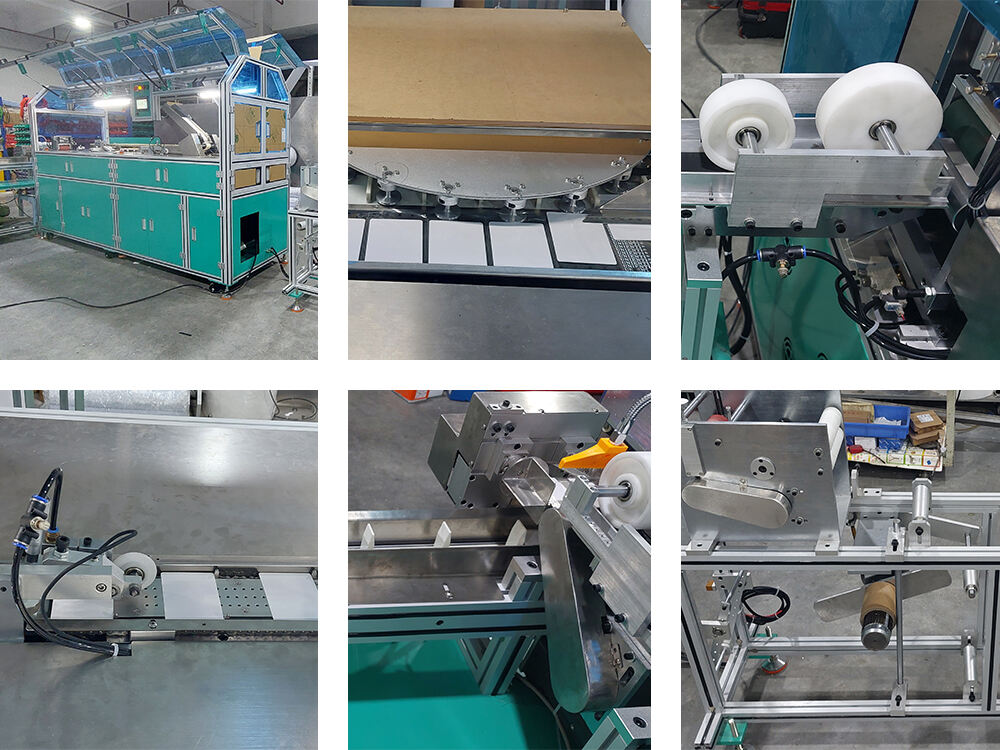

Before delving into the specific benefits, it is important to understand the role of card packaging machines in the overall smart card production line. The production of smart cards consists of several stages, including card manufacturing, personalization (embedding chips, printing data, etc.), testing, and finally, packaging. After the card has undergone personalization and passed quality checks, it must be packaged properly to ensure it reaches the customer in optimal condition. The packaging process involves:

A card packaging machine automates these steps, ensuring that the entire process is faster, more accurate, and more efficient than manual methods.

One of the most significant benefits of integrating a card packaging machine into the smart card production line is the substantial increase in speed and efficiency. Manual packaging processes are inherently slow and labor-intensive, limiting the number of cards that can be packaged in a given period. However, automated machines can handle thousands of cards per hour, greatly accelerating production and enabling manufacturers to meet the growing demand for smart cards.

These machines can handle multiple tasks simultaneously, such as sorting, counting, packaging, and labeling, which further reduces the time spent on each card. In high-volume production environments, this increased efficiency translates to shorter lead times, faster delivery to customers, and the ability to scale production quickly to meet market demands.

Manual packaging processes are prone to errors, which can result in incorrect packaging, missing cards, or damaged products. For instance, human workers might accidentally miscount the number of cards, place cards in the wrong packaging, or fail to apply labels correctly. These errors can lead to costly mistakes, delays, and customer dissatisfaction.

Card packaging machines eliminate the risk of human error by automating these tasks. Automated systems are highly precise, ensuring that each card is packaged according to the required specifications, with accurate counts, correct labels, and no damaged cards. This not only improves the overall quality of the product but also reduces the need for rework, saving both time and money.

While the initial investment in a card packaging machine may be substantial, it brings long-term cost savings. By automating the packaging process, manufacturers can reduce their reliance on manual labor, which lowers labor costs. This is particularly important in high-volume production environments, where large numbers of workers would be needed for manual packaging.

In addition to labor savings, card packaging machines also minimize material waste. For example, automated systems are capable of using the optimal amount of packaging material, reducing waste and ensuring that cards are packed efficiently. Furthermore, the increased speed of production means that manufacturers can produce more units in less time, improving overall productivity and reducing per-unit costs.

The proper packaging of smart cards is crucial to ensuring that they are protected during transportation and storage. Cards must be shielded from physical damage, such as scratches, bending, or exposure to environmental factors like moisture and dust. Automated card packaging machines ensure that each card is securely held in place within the packaging, preventing movement that could lead to damage.

Additionally, certain types of packaging, such as blister packs or custom-molded trays, provide extra protection for high-end cards that may contain sensitive components or valuable data. These machines can handle different types of packaging materials, ensuring that the cards are securely protected in transit and remain in pristine condition when they reach customers.

Consistency is critical in smart card production, especially for customers who require large quantities of identical cards. The use of a card packaging machine ensures that each card is packaged to the same standard, with consistent labeling, sorting, and packaging methods. This standardization not only improves the overall appearance of the final product but also ensures that the cards meet the exact specifications required by customers.

The ability to achieve consistent packaging results is particularly important for industries like banking or government, where cards need to meet specific security standards or customer preferences. By using automated packaging systems, manufacturers can ensure that their products remain compliant with industry regulations while also meeting the expectations of their clients.

The integration of card packaging machines into the smart card production line provides numerous benefits, the machine not only streamline the packaging process but also play a crucial role in maintaining high standards of quality and customer satisfaction. As demand for smart cards continues to rise and production requirements become more complex, the role of card packaging machines will become even more critical in ensuring that manufacturers can meet the needs of their clients while maintaining competitiveness in the marketplace. By embracing automation, smart card manufacturers can achieve greater efficiency, lower costs, and deliver superior products to their customers.